Environmental

Updated 4-28-2025

Treatment Systems

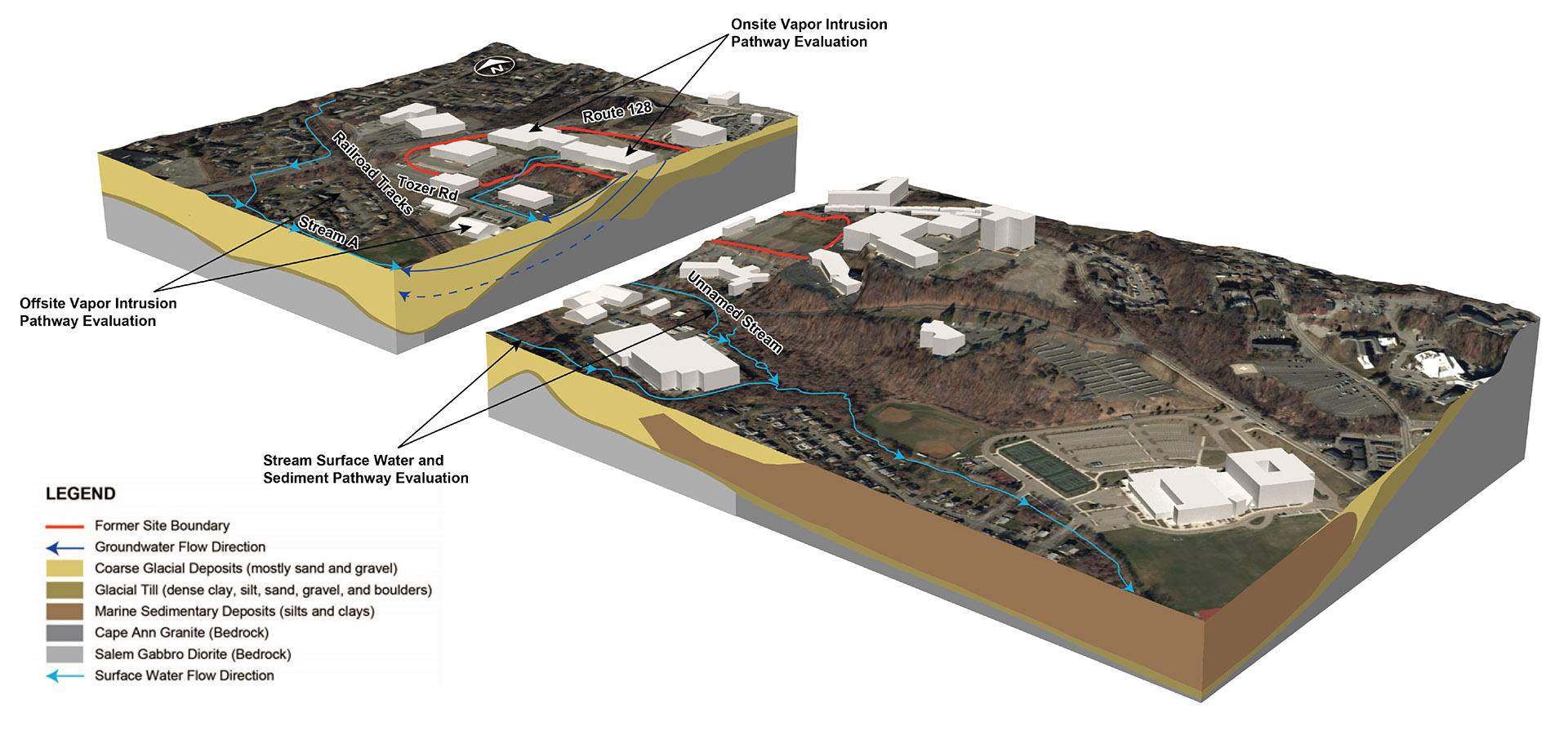

Environmental cleanup is focused on five project areas (see Figure 1):

Figure 1 Site Map and Selected Treatment Areas

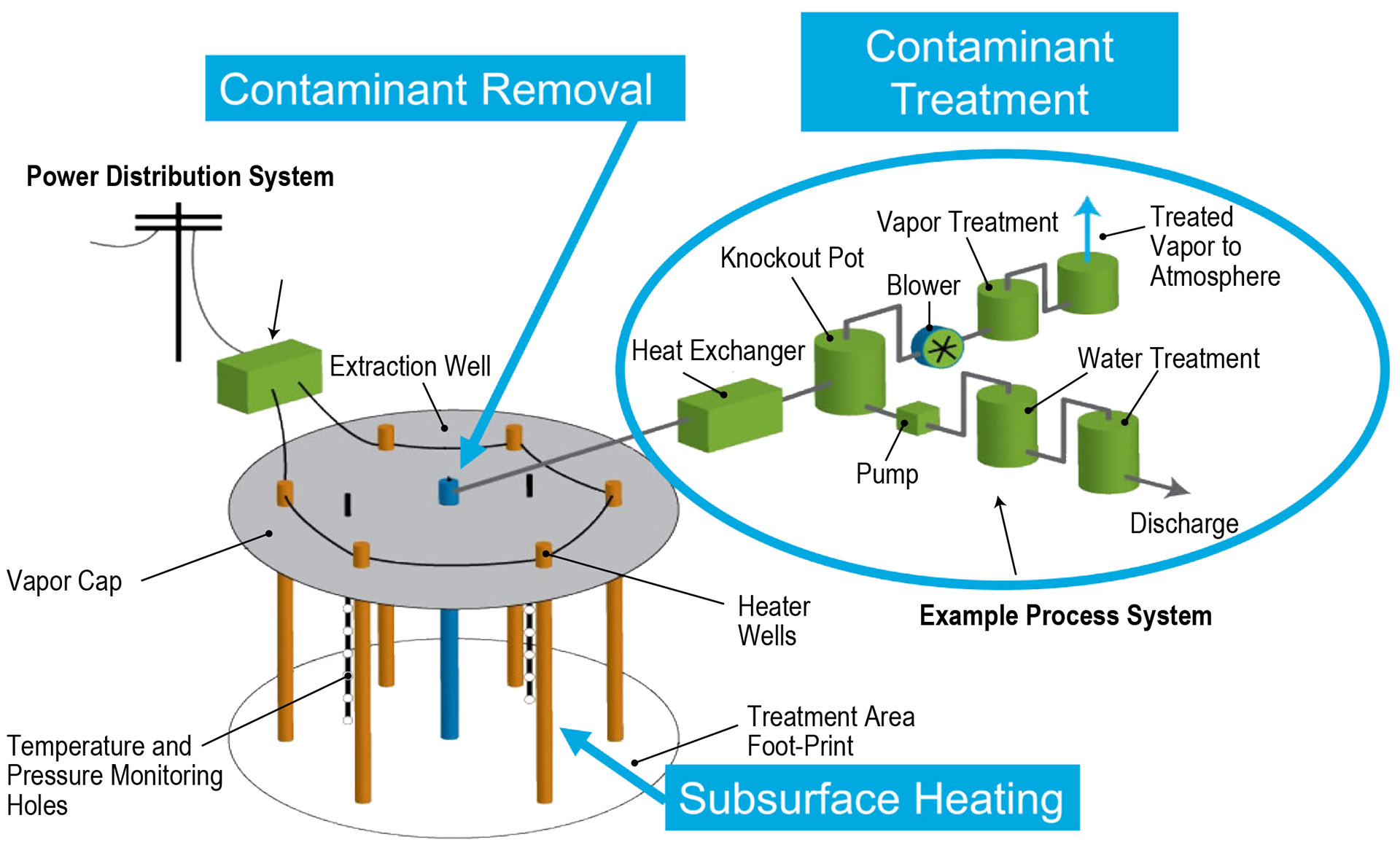

Figure 2 Diagram of a Thermal Treatment System

Building 3 Source Area – Thermal Treatment and Bioremediation

Groundwater next to and below Building 3 will be treated using thermal treatment, followed by bioremediation. Soil vapor extraction operation will continue using an upgraded system. The existing soil vapor extraction system is being replaced because it is not compatible with temperatures used during thermal treatment.

Thermal treatment involves installing heating elements deep into the ground below Building 3 and heating the groundwater to boiling. The heating elements are similar to the ones in a toaster, only larger. Heating the groundwater causes the volatile organic compounds to become vapors, which are captured by extraction wells that suck the vapors and some water to the surface for treatment using activated carbon. The activated carbon filters out the volatile organic compounds (in much the same way a household water filter does) and the clean vapors and water are released to the environment.

Following thermal treatment, bioremediation will continue to reduce volatile organic compound concentrations by taking advantage of the increased temperature underground. The warm groundwater that remains after thermal treatment provides an excellent environment for microbial growth. Certain microbes “eat” volatile organic compounds like trichloroethene (TCE) and tetrachloroethene (PCE). Bioremediation involves stimulating microbial growth by injecting amendments (such as vegetable oil or molasses) that the microbes use to grow and multiply, so they can consume more volatile organic compounds.

Throughout the treatment at the Building 3 source area, a soil vapor extraction system will continue to operate to protect site workers by preventing volatile organic compound vapors from entering the building. The soil vapor extraction system works by drawing vapors (by vacuum) from the soil below the building and treating them using activated carbon.

The current status of installation and operation of the treatment system is presented on the home page.

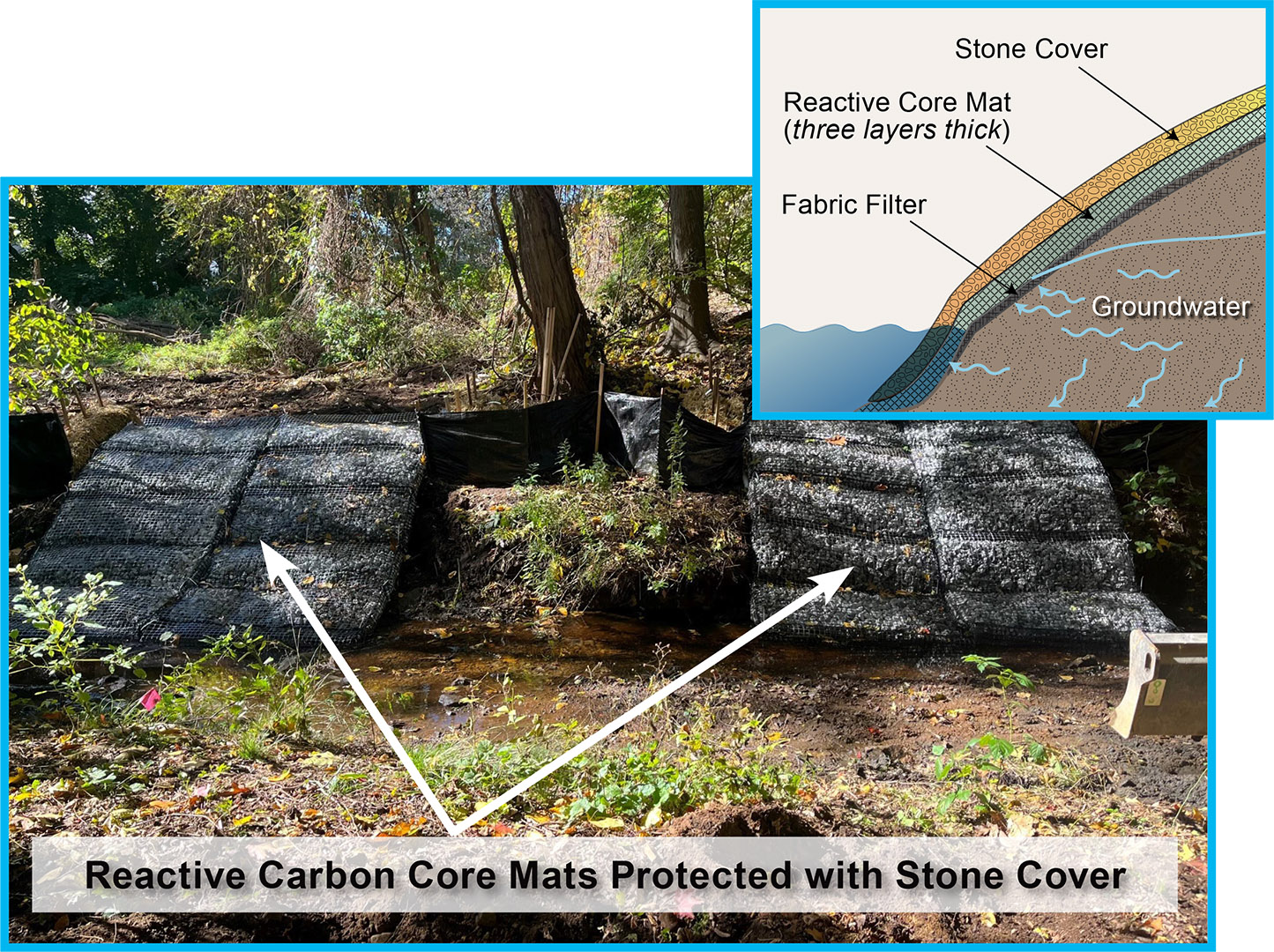

Stream A Seep – Permeable Adsorptive Barrier

At two seep areas along Stream A, a permeable adsorptive barrier was installed in October 2023 to capture volatile organic compounds in seepage water before it discharges to the stream. A reactive core mat containing granular activated carbon filters volatile organic compounds like a water filter. These compounds stick to the carbon inside the mat as the groundwater passes through. The mat is covered with stone to prevent access or damage.

The conservative risk assessment indicated that there is no significant risk to people or pets from contact with water from the stream. The seep treatment is being conducted as an additional protective measure.

The current status of installation and operation of the treatment system is presented on the home page.

Figure 3 Reactive Core Mat Installed at Stream A Seeps

Figure 3 Reactive Core Mat Installed at Stream A Seeps

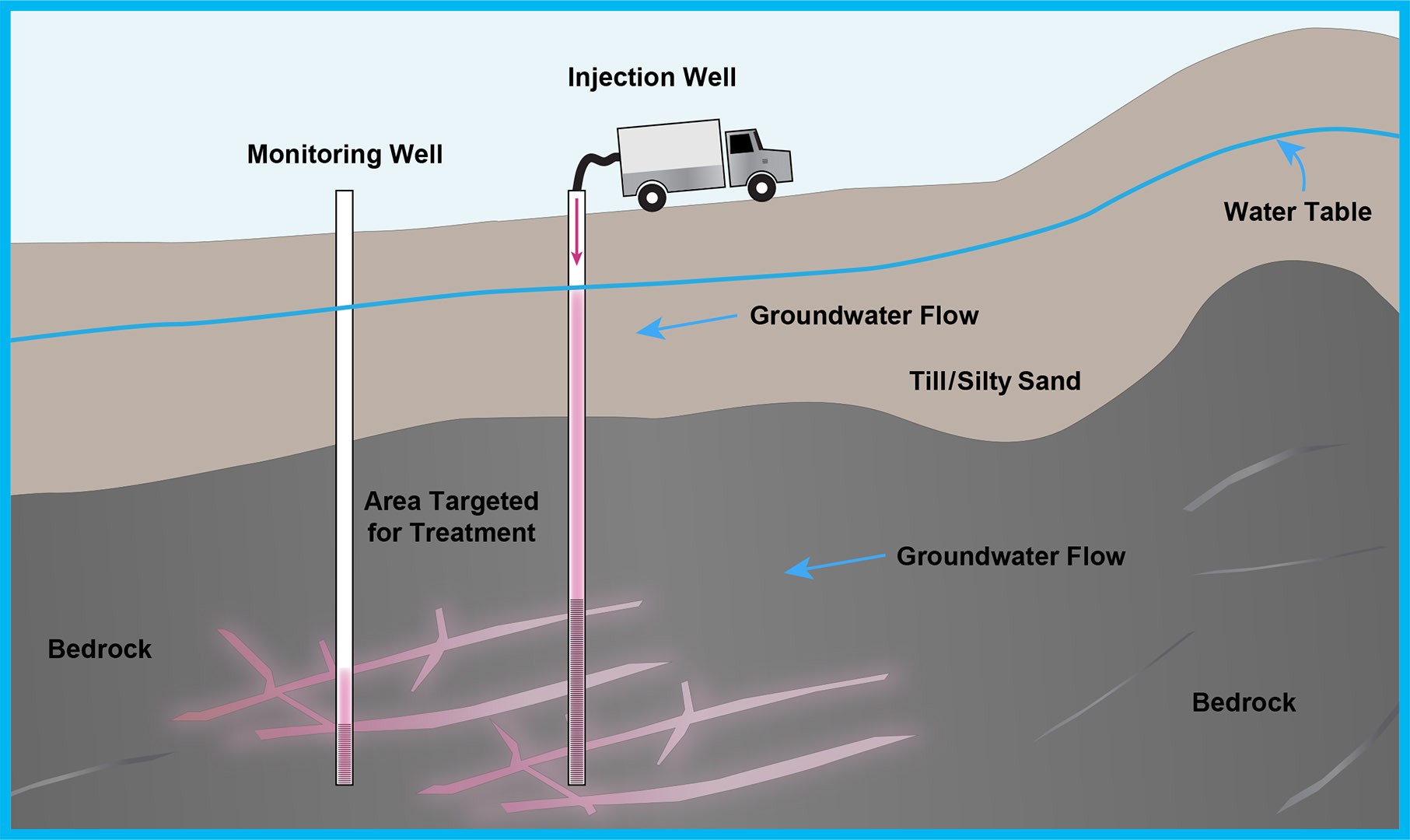

Figure 4 Bioremediation Treatment Zone and Injection Wells

Figure 4 Bioremediation Treatment Zone and Injection Wells

Building 5 Source Area – Bioremediation

The selected treatment technology for groundwater in the Building 5 area is bioremediation and continued operation of the current soil vapor extraction system.

Concentrations of volatile organic compounds in groundwater beneath Building 5 are significantly lower than beneath Building 3. Bioremediation has previously been successful where applied in the Building 5 area, and thermal treatment is less appropriate for areas with lower concentrations. Therefore, bioremediation will be expanded to new locations beneath the building and will use new application methods, such as high pressure or pulsed injections to address the deep groundwater. During the bioremediation treatment in the Building 5 source area, the existing soil vapor extraction system will continue to operate to protect building occupants.

The current status of installation and operation of the treatment system is presented on the home page.

Bedrock Near Buildings 3 and 5 – Chemical Reduction

A bedrock treatment area has been identified along the western boundary of the property between the Building 3 and Building 5 source areas. In that area, in situ (in place) chemical reduction will be implemented to treat elevated concentrations of volatile organic compounds in bedrock fractures (cracks in the rock) located well below the ground surface.

Pre-design investigations were conducted in 2024 to identify specific bedrock fractures to receive treatment. The investigation used tests to measure concentrations of volatile organic compounds within those fractures, and assess whether groundwater can flow through the fractures. These tests have shown that a portion of the bedrock fractures are “transmissive,” meaning that the groundwater readily flows through them; other bedrock fractures are “tight” meaning that not much groundwater flows through them. Because the transmissive fractures can serve as a migration pathway from the source areas to the downgradient area, the preferred treatment is chemical reduction, which uses an anaerobic (absence of oxygen) degradation process similar to those used upgradient (Building 3 and 5 source areas).

Chemical reduction involves injecting a mixture of emulsified vegetable oil and small particles of zero-valent iron to break down chlorinated volatile organic compounds that are present in the fractures. Contaminant degradation occurs through both chemical reactions with the zero-valent iron and biological reactions with the emulsified vegetable oil and microorganisms naturally present in the subsurface. Colloidal activated carbon will also be injected to immobilize volatile compounds in place.

More information about chemical reduction can be found HERE. The current status of installation and operation of the treatment system is presented on the home page.

Figure 5 Diagram of Chemical Reduction

Figure 5 Diagram of Chemical Reduction

PSL-10 Source Area – Soil Excavation with Permeable Treatment Zone

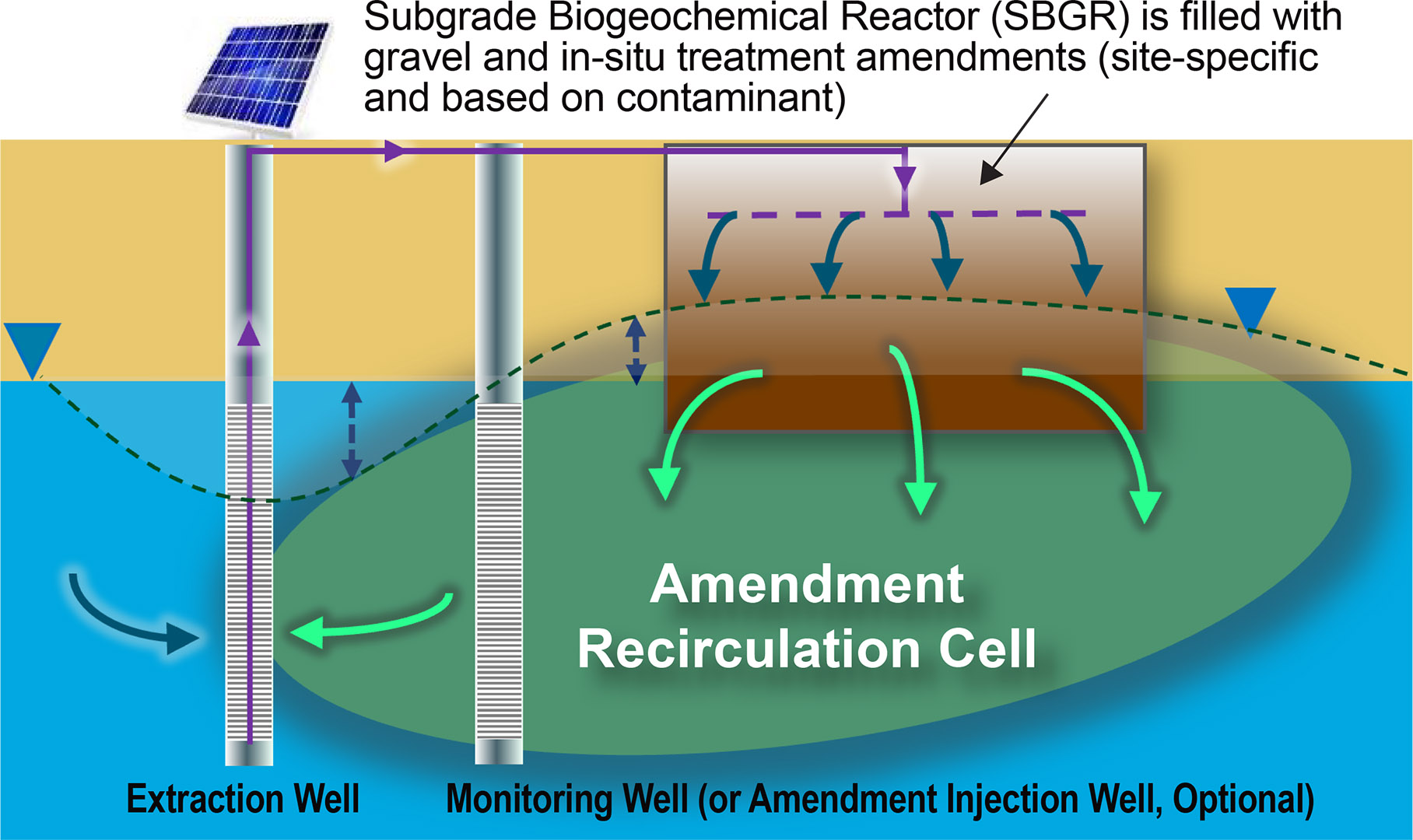

The selected treatment for the PSL-10 (Open Field) source area is a permeable treatment zone. Soil excavation is also planned to supplement this treatment. Additional pre-design investigations were completed in August-December 2023 to evaluate the type of permeable treatment zone that should be implemented. These investigations indicated that a relatively small, shallow area of soil may be contributing volatile organic compounds to groundwater in this area. When shallow soil contributes volatile organic compounds to groundwater, then a simpler and more effective remedy may be to excavate the soil, and then backfill the excavated area with amendments that will enhance biological and chemical breakdown of volatile organic compounds. Using a solar-powered pumping system, groundwater is recirculated through this backfilled material to provide continued groundwater treatment. This permeable treatment area is commonly referred to as a “subgradient biogeochemical reactor”.

The current status of installation and operation of the treatment system is presented on the home page.

Figure 6 Diagram of a Subgrade Biogeochemical Reactor

Figure 6 Diagram of a Subgrade Biogeochemical Reactor

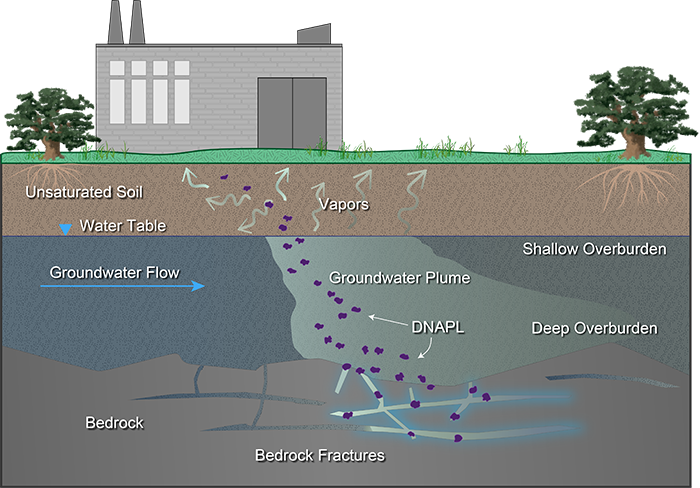

How is a Site Investigated for Volatile Organic Compounds?

Environmental investigation of a site with volatile organic compounds involves the following approach:

- Define the source area – the area with the highest concentration of chemicals, usually where the spill or leak occurred historically

- Define if and where chemicals have moved away from the source (nature and extent of contaminant presence)

- Requires an understanding of detailed site geology – soil, bedrock underlying soil, and groundwater in soil or bedrock fractures.

- Some chemicals sink down through the soil and groundwater until reaching an impermeable layer (e.g., clay) or bedrock and form a concentrated area of dense non-aqueous phase liquid (DNAPL).

- Some dissolved chemicals mix with and move with groundwater, forming a groundwater plume. Chemical migration in groundwater is slower than the movement of groundwater. Therefore, the ability of a chemical plume to move is limited. Groundwater can also upwell into surface water through streams and springs.

- Volatile organic compounds can evaporate from soil or groundwater and be carried to the surface through the soil in vapors. These vapors can enter a building through cracks in foundations or other preferential pathways such as sump pumps or sewer lines (known as “vapor intrusion”).

How is a Site Cleaned Up Under the Massachusetts Continency Plan (MCP)?

The Massachusetts Contingency Plan (MCP) is the process defined by state regulations that governs site cleanup in Massachusetts. The MCP outlines a phased approach to site investigation and cleanup.

Generalized Massachusetts Contingency Plan (MCP) Public Involvement Process

Phase I: Initial Investigation

• Initial investigations

• Implement preliminary response actions where needed

Phase I at Varian (click):

- Initial investigations at Varian started in the late 1980s; before the MCP

- Conducted groundwater pump & treat (1992-2002) to contain volatile organic compounds

Phase II: Comprehensive Site Assessment

• Determine nature and extent of contamination

• Evaluate potential risk to determine if cleanup plan is needed

Phase II at Varian (click):

- Original Phase II completed in 2000, treatment needed to address source areas

- A Phase II Addendum was completed in 2023, with an updated risk assessment that confirmed there is no significant risk to current workers or residents

Phase III: Remedial Action Plan

• Evaluate cleanup options based on defined criteria

(e.g., effectiveness, feasibility, comparative benefits, etc.)

Phase III at Varian (click):

- Original Phase III completed in 2001 and modified in 2012

- Pilot tests for pump and treat and chemical oxidation in 2001

- Pilot test for soil vapor extraction in 2012

- A Revised Phase III was completed in 2023; which included remedial action alternatives selected for six project areas: Building 3 Source Area, Building 5 Source Area, bedrock, PSL-10 Source Area, and the downgradient plume (i.e., Tozer Road Groundwater and Steam A Seeps)

Phase IV: Remedy Implementation

• Complete cleanup design and plans

• Begin treatment

Phase IV at Varian (click):

- Original Phase IV submitted completed in 2002 and 2012

- Implemented cleanup using chemical oxidation in 2002

- Implemented cleanup using soil vapor extraction supplemented with bioremediation in 2012

- Revised Phase IV Remedy Implementation Plans were submitted in three parts in 2023

- A Modified Phase IV Remedy Implementation Plan was submitted in April 2025

Phase V: Operation

and Maintenance

• Verify that cleanup continues to operate as planned

• Monitor remedy effectiveness

Phase V at Varian (click):

- Until 2022, periodic modifications to treatment with regular Phase V remedy operation status reporting to Massachusetts Department of Environmental Protection (MassDEP), along with groundwater and surface water monitoring

- Since 2022, operation, maintenance and monitoring continue and are reported to MassDEP as part of regulatory status reports. Starting in the second half of 2024, treatment progress is included in Temporary Solution status reports. Phase V remedy operation status reporting will resume once a Permanent Solution is achieved.

Permanent or Temporary Solution

• Determination that a site has been cleaned up to background levels, if feasible, or, if not, to levels of no significant risk.

Permanent or Temporary Solution at Varian (click):

- Temporary Solution Statement completed in 2024

- Permanent Solution expected to be achieved once treatment has been fully implemented at the site and is operating.

No Significant Risk is a regulatory term describing when a contaminant is either not detected or is below a level that would cause a defined level of increased risk to human health or the environment. At the Former Varian Facility Site, there is No Significant Risk to current residents and workers.

More information about Massachusetts’ Waste Site Cleanup Program can be found on the Massachusetts Department of Environmental Protection website.

All site reports associated with the MCP process, including inspection and monitoring reports, can be found in MassDEP’s online document portal.

Conceptual Site Model

Site investigators develop conceptual site models based on site data to portray contaminant sources, migration and exposure pathways, and receptors – the people and animals who are potentially exposed to contaminants. Conceptual site models evolve as new data are collected.